Testing of medical devices and equipment

Carrying out regular inspections, maintenance and other legally required tests ensures that your medical equipment is ready for operation and sustainable, guarantees the safety of patients, users or third parties and also fulfills the legal obligations towards the supervisory authorities.

As the operator of electrical medical devices or a healthcare facility, whether this is a doctor's practice, pharmacy, medical care center, hospital, clinic or care facility, you are liable to the legislator in accordance with the MPDG and MPBetreiberV if this obligation is not fulfilled.

Due to the various legal standards, it is often not entirely clear to you as the operator which type of test is mandatory for which type of appliance.

Technical safety check (STK)

The safety inspection is a periodic legally prescribed inspection of the actual safety-related condition of an active non-implantable medical device of Annex 1 in accordance with §11 MPBetreibV & DIN EN 62353, in which a device defect and risk features are detected and eliminated at an early stage. Compliance with the output parameters at the tolerance limit defined by the manufacturer for the intended use is also checked, e.g. whether an infusion pump maintains the set delivery rate or a defibrillator delivers the set amount of energy.

Examples of medical devices subject to STK:

- Defibrillatoren

- HF devices

- Infusion/injection pumps

- Patient monitoring monitors

- Stimulation current therapy and diagnostic devices

- External pacemaker

- TENS devices

- Ultrasound therapy devices

- Ventilators

- Dialysis equipment

- ECG devices

- Laser surgery devices

- Electric patient beds

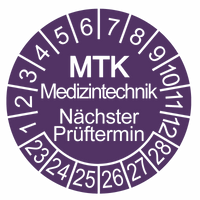

Measurement control (MTK)

The measurement check in accordance with §14 MPBetreibV for the medical devices listed in Appendix 2 must be carried out at regular intervals. The test serves to verify the measurement accuracy of the medical device to be tested so that measurement deviations do not exceed the maximum permissible error limit declared by the manufacturer.

Example of medical devices subject to MTK:

• Bike ergometer

• Blood pressure devices

• Audiometers

• Infrared thermometer

• Tonometer

Electrical safety testing of medical electrical devices and systems

All active (powered) medical devices and systems that are not subject to safety checks (STK) must undergo an electrical safety test in accordance with the international standard DIN EN 62353 (VDE 0751) at regular intervals.

The test mainly consists of visual inspection, electrical measurement (protective conductor resistance, insulation resistance, patient leakage currents, touch currents, etc.) and functional testing.